415D Draper

- John Deere

- Hileradoras

Buscar sucursal más cercana

Buscar ubicación

- La barra segadora y el perfil del bastidor permiten un caudal de cultivo ininterrumpido

- El carrete resistente, de alimentación positiva se adapta a todas las condiciones de cultivos

- Excelente visibilidad de la barra segadora y la correa

- El cambio de plataforma hidráulica permite hacer hileras más grandes para una cosecha más eficiente

- + Expandir todo

- - Cerrar todo

-

El carrete resistente, de alimentación positiva se adapta a todas las condiciones de cultivos

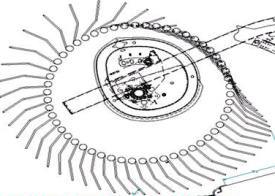

Molinete 1435D con división y dedos de plástico

Molinete 1435D con división y dedos de plástico

Acción de los dientes del molinete de leva

Acción de los dientes del molinete de leva

Molinete totalmente hacia adelante

Molinete totalmente hacia adelante

The cam real design of the 1400D Series Draper Platform features:

- 165-cm (65-in.) diameter

- Heavy-duty plastic or steel fingers

- Tooth position control

- Smoother and quieter operation at higher reel speeds

- Less wear on reel drive components

- Less shattering of the crop

Molinete con forma de reloj de arena

Molinete con forma de reloj de arena

Reel end fingers

Reel end fingers

The hourglass-shaped reel has:

- End positioned closer to the cutterbar to provide smooth feeding

- Adjustable bolt position to change distance of reel to cutterbar

Posiciones ajustables de las levas

Posiciones ajustables de las levas

Plastic fingers:

- Standard from the factory on all 1400D Series Platforms

- Recommended for all crop conditions

- Lighter weight and easy to replace

Steel fingers:

- Only available through Parts

- Recommended for heavy forage crop

- Longer life

Los dedos opcionales para los extremos mejoran la agresividad de la alimentación en condiciones de corte y alimentación difíciles con cultivos hacia abajo o enmarañados.

All 10,7-m (35-ft), 12,2-m (40-ft), and 13,7-m (45-ft) platforms come standard with tine tube stiffener kits to handle heavy crop conditions and improve the life of the platform.

Molinete dividido con púas de plástico y dedos de alimentación en los extremos

Molinete dividido con púas de plástico y dedos de alimentación en los extremos

Single span reel:

- 6-m (15-ft), 6,1-m (20-ft), 7,6-m (25-ft), 9,1-m (30-ft), and 10,6-m (35-ft) sizes

- Less weight

- Better center visibility

- Good option for canola and small grains harvesting

Double span reel:

- 6-m (35-ft), 12,2-m (40-ft), and 13,7-m (45-ft) sizes

- Better feeding in heavy, wet, or down crop

- Better control of the reel height for more consistent feeding

Molinete con cinco barras de púas

Molinete con cinco barras de púas

Molinete con seis barras de púas

Molinete con seis barras de púas

Molinete con nueve barras de púas

Molinete con nueve barras de púas

The reel is available in five-, six- or nine-bat configurations:

- Six- to nine-bat conversion is available with field installation

- Recommended for heavy conditions such as silage or grass seed crops

-

Las ruedas calibradoras permiten un seguimiento del terreno para lograr un corte uniforme

Opción de rueda calibradora dual

Opción de rueda calibradora dual

1400D Series Draper Platforms offer optional dual gauge wheels with spring suspension:

- 1-cm (15-in.)

- Excellent ground following and flotation in all conditions

- Fine adjust the float on the go from the cab for high-speed harvesting and stable flotation

- Available as part of the integrated slow-speed transport system option

-

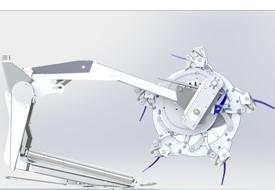

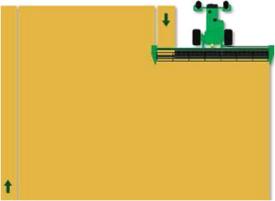

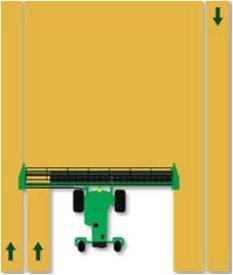

El cambio de plataforma hidráulica permite hacer hileras más grandes para una cosecha más eficiente

John Deere 1425D, 1430D, and 1435D Drapers can windrow out of the center, right, or left ends of the draper with the press of a button using the hydraulic shift option.

Hileras dobles utilizando el cambio de plataforma

Hileras dobles utilizando el cambio de plataforma

Hilera doble combinada

Hilera doble combinada

Hydraulic deck shift option:

- Larger windrows to match combine or self-propelled forage harvester

- Match narrower-width drapers with higher-capacity harvesting

- Place higher-density windrows in front of harvesters when yields are low

- Discharge two windrows side by side for uniform combine or forage harvester feeding

- Move chain stop to change center belt opening quickly and easily for different crop types and density (see operator’s manual for more information)

- Discharge crop to the outside of the headland to prevent running over the windrow while cutting the rest of the field

- Platform stays balanced with automatic fine-float adjustment when using deck shift

- Optional double draper drive bundle is recommended when using deck shift and harvesting silage or wet, heavy crops

- NOTE: The double draper drive option is not compatible with the 1425D Platform.

Primera pasada - descarga a la derecha

Primera pasada - descarga a la derecha

Segunda pasada - descarga a la derecha

Segunda pasada - descarga a la derecha

Tercera pasada - descarga a la izquierda

Tercera pasada - descarga a la izquierda

Varillas para formar hileras

Varillas para formar hileras

Optional left- and right-end swath deflector rods form a space between the windrow and uncut crop to have adequate clearance for the crop divider on the next pass.

-

Se transporta con facilidad con un sistema integrado de transporte

1400D integrated slow-speed transport system behind W170 Windrower

1400D integrated slow-speed transport system behind W170 Windrower

Slow-speed transport system:

- 1400D Drapers are towable only with the W170 Self-Propelled Windrower

- Transport is recommended behind a tractor with seven-pin electrical lighting outlet

- 1430D, 1435D, 1440D, and 1445D Drapers only

- Convert draper from field to transport in minutes with one person and without tools

- Dual front dolly wheel tires and two gauge wheel tires carry the weight of transport

Es un sencillo proceso de cuatro pasos para convertir de posición de campo a transporte:

- Move right gauge wheels from field to transport

- Move left gauge wheels from field to transport

- Attach the tongue.

- Detach from the windrower.

-

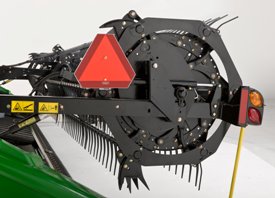

La barra segadora y el perfil del bastidor permiten un caudal de cultivo ininterrumpido

Perfil de la barra segadora en forma de C

Perfil de la barra segadora en forma de C

The C-shaped cutterbar profile provides:

- Smooth crop flow

- Superior draper-to-cutterbar seal

- Reduced amount of material under belts

- Minimized crop loss in shatter-prone crops

-

Excelente visibilidad de la barra segadora y la correa

Visibilidad de la barra segadora

Visibilidad de la barra segadora

Visibilidad a la derecha

Visibilidad a la derecha

Visibilidad a la izquierda

Visibilidad a la izquierda

The cutterbar design provides excellent visibility across the full range of tilt:

- Cutterbar and belt can be easily seen from the cab even with the optional top-crop conveying auger installed

- Cutterbar can be tilted from the cab mechanically or hydraulically depending on the windrower option chosen

- Change cutterbar angle with varying crop and field conditions for best cut height and crop flow

Sinfín superior auxiliar

| Tipo | Transmisión hidráulica opcional |

Abertura central/salida de cultivos

| Ancho de la abertura central entre correas | 1,72-1,95 mm 67,1-76,7 in |

| Capacidad de doble hilera/cambio de plataforma (manual/hidráulica/no disponible) | Manual estándar Hidráulico opcional |

Barra segadora

| Ancho de corte (longitud) | 10,7 m 35 ft |

| Velocidad de las cuchillas | Doble: 600-750 ciclos/min 1,2-1,5 spm Simple: 550-650 ciclos/min 1,1-1,3 spm |

| Tipo | Base estándar de dos cuchillas Base opcional de una cuchilla |

| Inclinación de la barra de corte | Hidráulica estándar Mecánica opcional (2,5-12,0 grados de inclinación) |

| Transmisión de cuchillas | Motor hidráulico a correa a caja oscilante de uso intenso |

Dimensiones

| Ancho de transporte, posición de campo | 11,1 m 36,3 ft |

| Longitud de la plataforma | 11,1 m 36,3 ft |

| Ancho de transporte sobre ruedas, menos divisores | 2,5 m 8,1 ft |

| Profundidad de operación general | Con divisores de cultivos: 2,6 m 8,7 ft |

| Longitud de transporte, enganche extendido | 13,9 m 45,6 ft |

Draper y plataformas

| Ancho de la correa | Drapers con capa delgada y ancha de caucho de 710 ml (24 oz): 1,26 mm 49,6 pulgadas |

| Velocidad de funcionamiento | 0-225 m/min. 0-742 fpm |

| Control de la velocidad | Hidráulica desde la cabina |

Ruedas calibradoras y transporte

| Sistema integrado de transporte de baja velocidad | Opcional, incluye ruedas calibradoras dobles |

| Ruedas calibradoras | Opcional |

Sensores de altura del cabezal

| Sensor de altura del cabezal desde el suelo | Retorno a la altura de corte estándar Ruedas calibradoras opcionales |

| Sensor de altura del cabezal sobre el suelo | Resortes flotantes en unidad de tracción |

Especificaciones clave

| Longitud de la plataforma | 11,1 m 36,3 ft |

| Ancho de transporte sobre ruedas, menos divisores | 2,5 m 8,1 ft |

| Ancho de la correa | Drapers con capa delgada y ancha de caucho de 710 ml (24 oz): 1,26 mm 49,6 hp/ft |

| Profundidad de operación general | Con divisores de cultivos: 2,6 m 8,7 ft |

| Longitud de transporte, enganche extendido | 13,9 m 45,6 ft |

| Tipo de molinete | Liberación ajustable de 4 posiciones de la leva de recolección |

| Ancho de corte (longitud) | 10,7 m 35 ft |

| Dedos | Plástico para uso intenso |

| Ancho de transporte, posición de campo | 11,1 m 36,3 ft |

| Barra segadora - tipo | Base estándar de dos cuchillas Base opcional de una cuchilla |

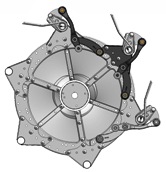

Molinete

| Control de altura | Hidráulico |

| Tipo de molinete | Liberación ajustable de 4 posiciones de la leva de recolección |

| Elevación del molinete | Hidráulico |

| Cantidad de paletas | 5 paletas de una graduación estándar División de 6 paletas de graduación opcional, extremos con tapa |

| Molinete hacia adelante y hacia atrás | Hidráulico |

| Dedos | Plástico para uso intenso |

| Diámetro | 1.650 mm 65 in |

| Control de la velocidad | Hidráulica con índice de cabezal |

| Velocidades de funcionamiento | 0-85 rpm |

Peso

| Peso aproximado (plataforma base con molinete) | 2,13-2,59 kg 4,7-5,7 lb |