Cosechadora de forraje con autopropulsión 9700

- John Deere

- Cosechadoras de forraje autopropulsadas

Buscar sucursal más cercana

Buscar ubicación

Características y especificaciones

- HP: 813 Max / 789 Rated

- JD18X 18 L engine

- New spout with improved crop flow and visibility

- Field-proven kernel processing options

- Ancho del canal Ancho

- Potencia nominal 755 HP

- Motor JD18X

- Capacidad del tanque de combustible 396 gal (1500 L)

- Desplazamiento 18 L

- + Expandir todo

- - Cerrar todo

-

High forage quality with HarvestLab™ 3000 and AutoLoc™ system

HarvestLab 3000 measures dry matter and constituents on the go

HarvestLab 3000 measures dry matter and constituents on the go

HarvestLab 3000 sensor mounted on the spout

HarvestLab 3000 sensor mounted on the spout

The HarvestLab 3000 sensor mounts to the top of the discharge spout and takes accurate dry matter and ingredient readings (more than 4000 measurements per second) of the crop through the sapphire glass lens as crop passes through the spout. Es la misma tecnología usada por los laboratorios de forraje para medir la materia seca. HarvestLab 3000 with John Deere Constituent Sensing measures dry matter and constituents like sugar, starch, acid detergent fiber (ADF), neutral detergent fiber (NDF), crude fiber, crude ash, crude protein, crude fat, Metabolic Energy and ELOS depending on the crop. In addition, the HarvestLab 3000 sensor can also be used as a stationary unit.

Stationary usage of HarvestLab 3000

Stationary usage of HarvestLab 3000

Crop type and constituent sensing

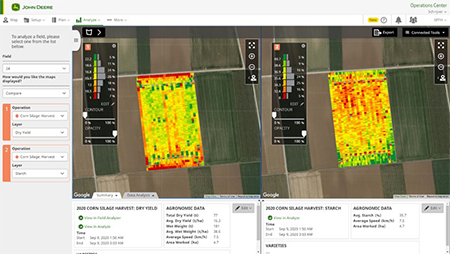

Tipo de cultivo Moisture/ dry matter Crude protein Crude starch uNDF ADF Crude sugar Crude Ash Maíz X X X X X --- X Alfalfa X X --- X X X X Ensilaje de cultivo completo X X X X X X X Hierba X --- --- --- --- --- --- When HarvestLab 3000 is used in conjunction with Harvest Monitor™ system, a wealth of important information becomes available to the operator, including productivity in acres per hour, throughput in tons per hour, total area harvested, total crop mass harvested, yields, and dry matter. To measure and document the constituents, a Gen 4 4640 Universal Display is required. All data documented on the Gen 4 4640 Universal Display is shown in John Deere Operations Center.

Constituent data in Operations Center

Constituent data in Operations Center

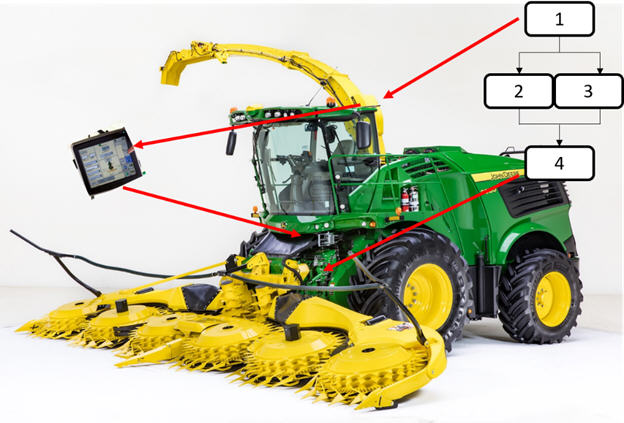

When the HarvestLab 3000 is used in conjunction with an 8000 or 9000 Series Self-Propelled Forage Harvester (SPFH) and a GreenStar™ display, AutoLoc functionality is automatically present. AutoLoc automatically varies the length of cut according to the desired crop-dry matter correlation settings based on the dry matter readings from the HarvestLab 3000 sensor. With the AutoLoc adjustment, bunk density is improved and a high forage quality is reached.

AutoLoc - Automatic length of cut

AutoLoc on the SPFH

AutoLoc on the SPFH

- HarvestLab 3000 — moisture and ingredients on the go

- Manual control (operator)

- AutoLoc — automatic control

- IVLOC™ transmission — length of control changes on the go

AutoLoc, a feature exclusive to John Deere and unique to the market, brings added value to the HarvestLab sensor and John Deere SPFH. AutoLoc works in conjunction with the HarvestLab 3000 sensor and IVLOC transmission to automatically adjust the length of cut (LOC) based on crop moisture levels to improve bunk density and reduce long particles in dry corn. Nutritionists, herdsmen, and SPFH operators will all benefit from this innovation.

John Deere is leading the industry in providing real-time information that matters most to forage production. Quality forage comes from properly packed silage, which is directly related to the moisture content and LOC of the crop.

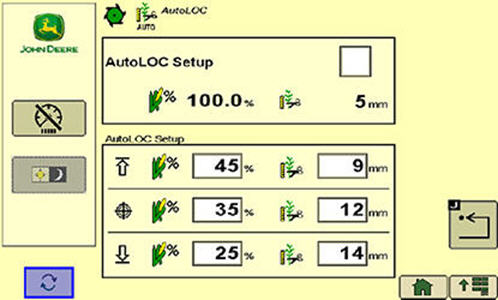

LOC changes are made automatically in the field based on moisture readings and predetermined settings determined by operator requirements. No in-field calibration is required to load the LOC requirements; the operator simply uses the GreenStar™ display to program the desired LOC settings at different moisture levels.

When moisture levels of crop in the field change, the IVLOC drive automatically responds to either increase or decrease the feedroll speed, which in turn changes the LOC. If moisture levels of the crop are outside of the desired range, the IVLOC transmission adjusts and limits the LOC based on the maximum and minimum LOC settings as determined by the operator. AutoLoc screen

AutoLoc screen

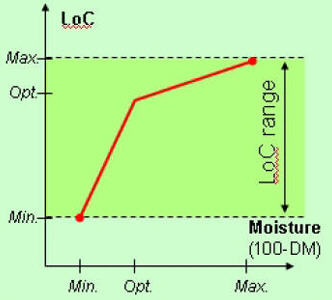

AutoLoc solves the dry matter and LOC puzzle

According to the accurate moisture readings, AutoLoc is able to adjust the proper LOC automatically in steps as small as 1 mm (0,04 in.). This process is faster and more accurate than any operator could do manually because of all the other important operating functions being performed. This can increase overall efficiency dramatically.

With AutoLoc, the SPFH operator simply sets the minimum, optimum, and maximum moisture levels and the corresponding lengths of cut. AutoLoc then creates a linear curve between the minimum and the optimum and between the optimum and the maximum. LOCs are then determined based on those lines.

For example, if the optimum LOC were set to 15 mm (0,59 in.) at 68 percent moisture and 8 mm (0,31 in.) at 50 percent moisture, and the actual moisture of the crop was 63 percent, AutoLoc would change the LOC to be 13 mm (0,51 in.) based on the linear curve it created. AutoLoc chart

AutoLoc chart

Forage harvester performance and AutoLoc

The following equipment is required for AutoLoc functionality:- GreenStar display with Gen 4 4640 Universal Display

- HarvestLab 3000 sensor

- 8000 or 9000 Series SPFH

Why AutoLoc is a must to ensure silage quality and overall profitability

It impacts the silage compaction in the bunker to ensure the quality of feed being stored is the best quality possible.

Silage density and AutoLoc

Good silage starts with high bunk density to preserve the crop value. This is the main objective for both dairy/beef producers and biogas plants. Many factors are involved in achieving high bunk density, including type of crop, moisture levels, length of cut, bunk filling speed, and compaction machinery.

Some of these factors cannot be easily changed while harvesting. AutoLoc adds an improved sense of control to the harvesting and silage storage operation. Operators do not need to compromise when choosing the proper length of cut based on moisture. AutoLoc takes care of this chore automatically.

Oftentimes, producers are so focused on getting the job done that important tasks and details are overlooked during the harvesting operation. Knowing the growing period for corn silage covers five months growing in the field and only a few days harvesting for 10 to 12 months of feeding, the process of the silage harvest and storage should be managed as well as possible.

The impact of the silage quality, which can be harvested and stored in just a few days, can have a huge impact on income throughout the entire year. The silage cost is a major part of the expenses in the dairy/beef and biogas plant businesses. Poor forage quality can cost tens of thousands of dollars per year in increased feed costs resulting in the producer having to invest in additional silage to reach the desired feed ration.

Spoilage/reheating and seeping losses are the biggest problems in silage bunks. These problems often happen due to insufficient compaction and an incorrect LOC. To achieve the right amount of silage compaction and keep as much air out of the silage as possible, the LOC has to be adjusted according to the moisture levels of the crop - the wetter the material, the bigger the particle size.

While varying lengths of cut can dramatically help to achieve high density levels, the length of cut of the material must be consistent in order to maintain normal rumination, chewing, and saliva production in the rumen. If the particles are too small, the food does not fit anymore with the process of the cow rumen and the compaction becomes difficult due to the instability of the material.

For this reason, John Deere created AutoLoc, which automatically adjusts the length of cut to the moisture value, while staying within the preset LOC range.

Having some limited LOC variations in a bunk silo should not affect the effective fiber in the ration on a daily basis. Using AutoLoc in conjunction with upright or bag silos can vary the effective fiber fed to animals on a daily basis.

Looking at the studies done by Honig and Rohr in 1985, as can be seen in the following table, it is possible to get high-density levels of dryer crop when the crop is chopped at a shorter LOC.Longitud de corte

Bunk density

73 percent moisture

64 percent moisture

4 mm (0,16 in)

205 kg/m3 (12,8 lb/cu ft)

179,7 kg/m3 (11,2 lb/cu ft)

7 mm (0,28 in)

192,2 kg/m3 (12 lb/cu ft)

174,6 kg/m3 (10,9 lb/cu ft)

14 mm (0,55 in)

173 kg/m3 (10,8 lb/cu ft)

157 kg/m3 (9,8 lb/cu ft)

-

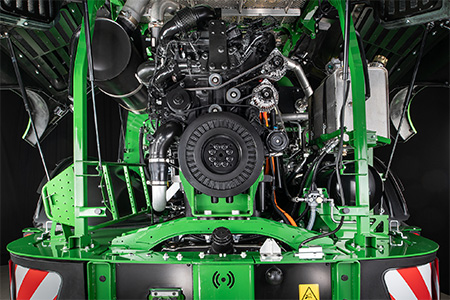

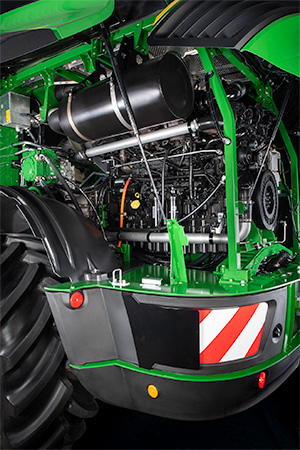

Powerful John Deere JD18X engine

John Deere 18L (1098-cu in.) JD18X engine

John Deere 18L (1098-cu in.) JD18X engine

The John Deere JD18X engine with 18L (1098-cu in.) displacement delivers unmatched performance and characteristics. The unique engine characteristic and efficiency brings the John Deere self-propelled forage harvesters (SPFH) into another performance league in the 700- to 800-PS (690,4- to 789-hp) power class. With the JD18X engine comes unique features and high comfort on the 9500, 9600, and 9700 SPFH models.

- Perfect engine characteristic for SPFH application

- Diesel only engine – no diesel exhaust fluid (DEF)/AdBlue® with Final Tier 4 (FT4)/ Stage V (EU) emission regulations

- HarvestMotion Plus

- Long engine oil service interval (750 hours)

The JD18X engine was awarded “Diesel of the Year 2021,” confirming the performance and the Diesel only concept. Click here for more information.

Diesel of the Year award

Diesel of the Year award

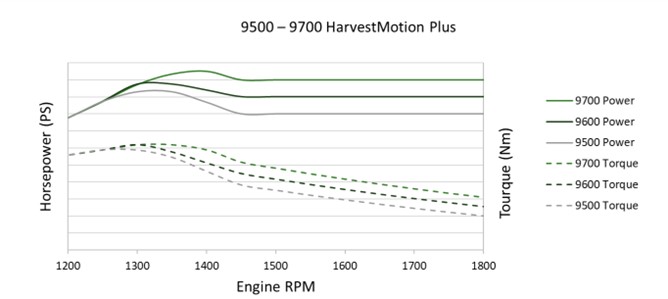

The unbeatable performance of the JD18X engine together with the HarvestMotion Plus concept achieves unique power and torque rise in the 700- to 800-PS (690,4- to 789-hp) power class.

Power and torque rise through engine rpm on the 9500-9700 SPFH

Power and torque rise through engine rpm on the 9500-9700 SPFH

The unique engine characteristics with constant, strong power and torque rise at around 1300 rpm provides a highly efficient forage harvester and comfortable driving in every situation.

Modelo Potencia nominal Maximum power with HarvestMotion Plus Power growth at lower rpm Aumento del par de torsión 9500 700 PS (515 kW, 690,4 hp) 765 PS (563 kW, 755 hp) 65 PS (48 kW, 64,4 hp) 9,3 por ciento 50,5 por ciento 9600 750 PS (552 kW, 740,2 hp) 787 PS (579 kW, 776,5 hp) 37 PS (27 kW, 36,2 hp) 4,9 por ciento 45,2 por ciento 9700 800 PS (589 kW, 789 hp) 825 PS (607 kW, 813 hp) 25 PS (18 kW, 24 hp) 3,1 por ciento

AdBlue is a trademark of VDA Verband der Automobilindustrie e.V. -

La alimentación de gran capacidad permite un ensilaje de alta calidad

Cabezal con tecnología de alta gama

Las unidades cosechadoras rotativas John Deere están diseñadas para ofrecer una alimentación potente y confiable en unas cosechadoras de forraje de gran capacidad. Dos diseños fundamentales satisfacen todas las necesidades del productor. Los cabezales de la serie 600plus son la solución universal para diferentes cultivos de hasta 4 m (13,1 ft) de altura. Los cabezales de la serie 700plus son la solución perfecta para cultivos de gran rendimiento.

Unidad cosechadora rotativa 772

Unidad cosechadora rotativa 772

El modelo superior de la unidad cosechadora rotativa 772 de 12 filas y tambor grande, disponible a partir de 2019, se ha diseñado para aprovechar al máximo la capacidad de las cosechadoras de forraje autopropulsadas (SPFH) de la serie 9000.

Recolector de hileras de la serie 6X9

Recolector de hileras de la serie 6X9

Los recolectores de la serie 6X9 con el diseño patentado de sinfín de hélice infinita y la transmisión de doble cabezal opcional permiten una alimentación de gran capacidad de las SPFH John Deere. Sus ventajas clave son el aumento de producción en cultivos de gran rendimiento y la manipulación sencilla de hileras irregulares.

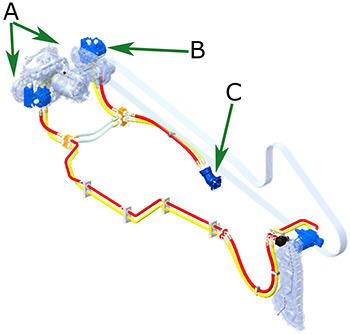

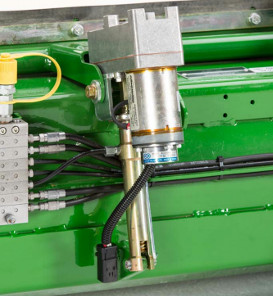

Transmisión de cabezal variable

Caja de engranajes para distribución de potencia (A), bomba del cabezal (B) y motor del cabezal (C)

Caja de engranajes para distribución de potencia (A), bomba del cabezal (B) y motor del cabezal (C)

Las SPFH John Deere tienen transmisión de cabezal variable de manera estándar. La velocidad del cabezal se sincroniza automáticamente con la velocidad de alimentación y la longitud de picado mediante un sistema de transmisión hidrostática IVT™. Esto garantiza una transferencia suave y uniforme del cultivo desde el cabezal al interior de la máquina sin bloqueos ni transiciones que perjudiquen el material. El productor se beneficia de la gran calidad del picado y de un aprovechamiento completo de las posibilidades del cabezal y el caudal de cultivo.

Transmisión de doble cabezal

La transmisión de doble cabezal de las SPFH y los recolectores de la serie 6X9 complementa las ventajas de la transmisión de cabezal variable. Mientras que la transmisión de cabezal variable sincroniza automáticamente el sinfín de recolección y la velocidad de alimentación de la cosechadora, la transmisión de doble cabezal, con su transmisión hidráulica individual de las púas de recolección, equipara su velocidad con la del vehículo para asegurar una recolección de cultivo prolija en condiciones e hileras cambiantes.

Sincronización de velocidad entre la SPFH y el cabezal

Sincronización de velocidad entre la SPFH y el cabezal

Las púas se aceleran y desaceleran con la velocidad de avance, mientras que la velocidad del sinfín del recolector sigue sincronizada con la longitud del picado y la velocidad del rodillo de alimentación. El productor se beneficia de un picado de mayor calidad, una alimentación más suave y un sistema recolector de uso sencillo.

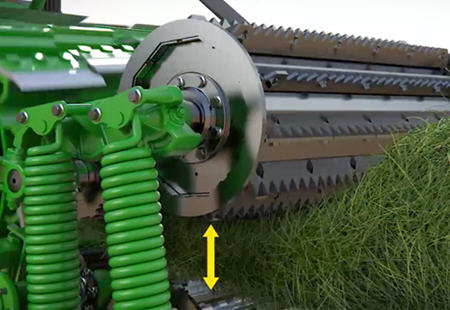

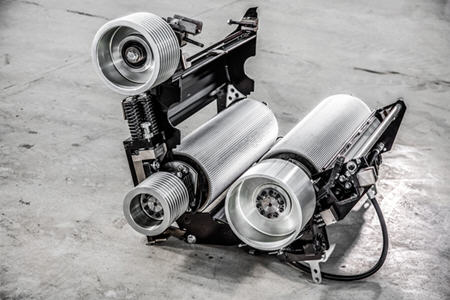

Amortiguación hidráulica del rodillo de alimentación

Todas las SPFH de la serie 9000 incluyen la amortiguación hidráulica del rodillo de alimentación. Junto a los cuatro resortes individuales diseñados para aplicar gran presión al material de cultivo que entra en la máquina, el amortiguador permite compactar cultivos en condiciones irregulares y garantiza una alimentación continua, incluso a velocidades de alimentación máximas, cuando se pica durante períodos muy largos.

Amortiguación hidráulica del rodillo de alimentación

Amortiguación hidráulica del rodillo de alimentación

Compactación del cultivo y alimentación uniforme en el rodillo de alimentación

Compactación del cultivo y alimentación uniforme en el rodillo de alimentación

Protección exclusiva contra objetos extraños

Un avanzado detector busca metales en la capa de material y detiene la admisión cuando se activa. De forma opcional, este dispositivo de seguridad puede completarse con una función exclusiva de detección de piedras que detecta golpes y movimientos anormales del rodillo de alimentación. Dos sensores redundantes creados para esta aplicación mejoran la detección de objetos extraños macizos y minimizan las activaciones falsas causadas por terrones o hileras irregulares.

-

Efficient, powerful, and reliable HarvestMotion Plus concept

A state-of-the-art engine with ideal performance characteristics and low specific fuel consumption perfectly aligns and synchronizes with a superior crop flow. This is the John Deere HarvestMotion Plus concept. The "Plus" stands for unique torque rise and more power at low engine rpm - an experience of pure performance and efficiency without any compromise. Additionally, there is no diesel exhaust fluid (DEF) required.

The HarvestMotion Plus advantage:

- 13 percent less fluid consumption (diesel plus DEF)

- 48 kW (64,4 hp) of extra power at low engine rpm to easily digest peak loads

- Simple is strong – reliable harvest capacity

John Deere 9000 Series with JD18X engine

John Deere 9000 Series with JD18X engine

Leading efficiency

With a maximum engine speed of 1800 rpm, the engine is always operated in its sweet spot. Lower rpm means lower specific fuel consumption. Less fuel consumption means less costs and, in the end, more money in your pocket. HarvestMotion enables up to 13 percent less total fluid consumption, which equals up to $125 per day of grass harvest and $141 per day of corn harvest.*

*NOTE: Based in internal benchmark data from 2020: JD18X engine with HarvestMotion Plus versus replaced model with 4 percent less diesel, no DEF (AdBlue®), and 10 hours of chopping per day.

Powerful heartbeat

Less engine rpm, more power, and a unique torque rise - this is what HarvestMotion Plus delivers. The JD18X engine has been tailored to the needs of an agricultural harvesting machine. Operators will feel its strength, and owners will profit off its harvesting capacity. The 18L (1098-cu in.) John Deere engine in the 9000 Series Self-Propelled Forage Harvester (SPFH) with the HarvestMotion Plus concept is a winning combination.

Reliability through simplicity

Reliable power delivered by modern robust engine technology ensures harvesting capacity. The JD18X engine delivers exceptional performance without needing a complex aftertreatment system. This means unique simplicity in this power class.

AdBlue is a trademark of VDA Verband der Automobilindustrie e.V. Liebherr is a trademark of Liebherr-International AG.

-

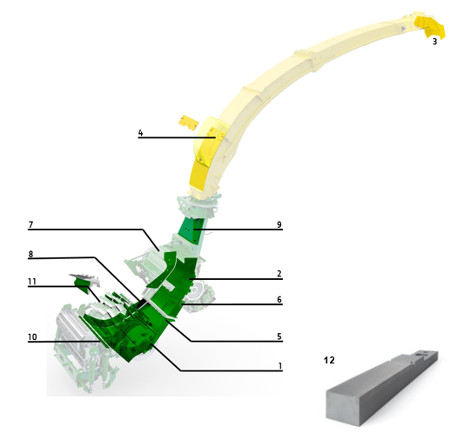

Dura Line™ wear parts

Resumen

Due to increased machine usage (chopping more tons per hour), standard high-quality steel parts need to be replaced more frequently. Since 2010, John Deere has been meeting the challenge and exceeding expectations with Dura Line wear parts.

Dura Line components were developed by John Deere and are installed in high wear spots on the self-propelled forage harvesters (SPFH), mainly in the crop flow. The technology is normally used for heavy-duty environments such as mining and machine tooling. It is the highest material quality in the industry that is installed on an SPFH.

Beneficios

- The coating is extremely wear resistant with an extraordinarily smooth surface due to the special heat treatment and a proprietary tungsten carbide composition.

- Dura Line™ provides a permanent fast-chopping process with low crop friction on the components while fuel consumption remains low.

- Tests show that when chopping in the same crop conditions and chopping the same tonnage, Dura Line parts last four times as long as, or longer than, standard parts. El tiempo y los costos asociados a la sustitución de partes se reducen significativamente.

Dura Line coating

Dura Line coating

Dura Line processing

Dura Line processing

Additional details

Dura Line guarantee

The Dura Line guarantee provides a specified number of engine hours or time of usage (whichever comes first) for the different Dura Line liners. The Dura Line guarantee was first introduced in 2017 and is valid for all 8000 and 9000 Series SPFH models. Dura Line liners damaged from foreign material or misuse are excluded. Only parts that are completely worn are replaced.

For more information about the Dura Line guarantee, contact the local sales organization.

Paquetes Dura Line

The John Deere Dura Line crop flow liners come in three packages. Depending on the individual harvesting requirements, there is a perfect package for every need.

- Basic: Perfect solution for machines mainly harvesting corn

- Premium: Ideal for abrasive conditions (particularly grass)

- Ultimate: Perfect choice for toughest conditions, providing full crop flow coverage

Dura Line wear parts

Dura Line wear parts

# Dura Line component Basic Premium Ultimate 1 Spiral band √ √ √ 2 Banda de aceleración √ √ √ 3 Deflector de descarga √ √ √ 4 Revestimiento resistente al desgaste del tubo de descarga √ √ 5 Revestimiento base de rampa deslizante frontal √ √ 6 Revestimiento base de rampa deslizante de hierba √ 7 Revestimiento de pared lateral del acelerador √ 8 Revestimientos laterales de rampa deslizante frontal √ 9 Transition front liners √ 10 Dura Line™ smooth roll scraper √ √ √ 11 Dura Line™ knife holder √ 12 Dura Line™ Plus shear bar √ √ -

Improve silage quality with two kernel processing options

Resumen

John Deere self-propelled forage harvesters (SPFH) set new standards in kernel processing performance. Proven in independent tests during corn harvest in 2016 and 2017, John Deere kernel processors (KP) deliver smashed kernels and highly processed plants that growers expect. With two different models, the John Deere Premium KP™ kernel processor and the John Deere XStream KP™ kernel processor, all different needs will be satisfied.

Additional details

All John Deere SPFH can be operated with or without a kernel processing unit in position. When not in use, a crop transition chute (or grass chute) swings into position with a few turns of a crank. La rampa de transición de cultivo se incluye en todas las cosechadoras como característica estándar.

The SPFH feature the AutoLube central greasing harness; the respective central greasing equipment is available on the Premium KP kernel processor. The XStream KP kernel processor features automatic pressurized oil lubrication.

The John Deere Premium KP is available for the 9500 to 9800 models, and the John Deere XStream KP is available for all 9000 Series models. The 9900 model can only be equipped with an XStream KP.

John Deere Premium KP

John Deere Premium KP kernel processor

John Deere Premium KP kernel processor

On the 9000 Series, the proven John Deere Premium KP can be installed on the 9500 through 9800 models. With their highly intense processing, they deliver excellent forage quality at any length of cut.

The main features of the Premium KP are:

- 240-mm (9,45-in.) roll diameter for different crops (maize and whole crop)

- 32 percent speed differential; option of 40 percent speed differential

- Standard KP housing with grease lubrication in base

- Electric KP gap adjustment from the cab as option

Para el Premium KP están disponible los siguientes rodillos:

- Standard sawtooth (118/118 teeth)

- Dura Line™ sawtooth (118/118 teeth)

- Whole crop sawtooth (178/178 teeth)

With the option of Dura Line rolls, a longer lifetime and less wear can be reached, resulting in lower cost of operation.

For easy and uncomplicated mounting and dismounting of the KP, a crane with electric winch can be installed as an option.

Mounting and dismounting the KP with the optional crane and winch

Mounting and dismounting the KP with the optional crane and winch

The following diagram shows the complete John Deere Premium KP offering with all possible combinations.

Sawtooth (118/118 teeth) – code 3734

John Deere Premium KP with:

- Standard KP housing

- 240-mm (9,45-in.) roll diameter

- 32 percent speed differential

- Grease lubrication

Dura Line sawtooth (118/118 teeth) – code 3738

Whole crop sawtooth (178/178 teeth) – code 3743

The following additional options are also available for the Premium KP.

Crane for KP removal complete with electrical winch (code 8380)

Crane for KP removal complete with electrical winch (code 8380)

Hydraulic KP belt tensioner (code 8381)

Hydraulic KP belt tensioner (code 8381)

Electrical KP gap adjustment (code 8376)

Electrical KP gap adjustment (code 8376)

40 percent speed differential (code 9389)

40 percent speed differential (code 9389)

Complete whole crop KP as bundle (code 9379)

Complete whole crop KP as bundle (code 9379)

John Deere XStream KP

John Deere XStream KP kernel processor

John Deere XStream KP kernel processor

The John Deere XStream KP is the heavy-duty solution made for high throughput and high-horsepower machines and stands for extreme processing at any length of cut in any crop and any conditions.

The XStream KP rolls are manufactured and delivered by Scherer Inc., located in South Dakota, United States. The kernel processor is supplied ex-factory by Scherer Inc. and fits on all 9000 Series models. As Scherer Inc. has a strong focus on dairy forage production and is the leading company in KP roll designs and manufacturing since 1999, a strong statement is set regarding kernel processing and forage quality.

More information about Scherer Inc. can be found on their website: http://www.schererinc.com/

Scherer Inc. logo

Scherer Inc. logo

The main features of the XStream KP are:

- 250-mm (9,8-in.) roll diameter

- 50 percent speed differential

- Heavy-duty housing with KP roll quick-exchange system

- Pressurized oil lubrication of bearings

- Bearing temperature monitoring system (option)

Para el XStream KP están disponible los siguientes rodillos:

- Dura Line sawtooth (110/145 teeth)

- Dura Line XCut (110/145 teeth)

- Dura Line Whole Crop XCut (145/165 teeth) – only available for 9000 Series

All XStream KP options for 9000 series are available with 10- or 11-inch rolls.

In comparison to the Dura Line sawtooth rolls, the Dura Line XCut rolls have a spiral groove sawtooth profile that delivers excellent processing, especially at long lengths of cut. El diseño de ranura en espiral proporciona plantas muy procesadas y granos aplastados.

For easy and uncomplicated mounting and dismounting of the KP, a crane with electric winch can be installed as an option.

Mounting and dismounting the KP with the optional crane and winch

Mounting and dismounting the KP with the optional crane and winch

The following diagram shows the complete John Deere XStream KP offering with all possible combinations

Dura Line sawtooth (110/145 teeth) – code 3750

John Deere XStream KP with:- Heady-duty housing

- 250-mm (9,8-in.) roll diameter

- 50 percent speed differential

- KP roll quick-exchange system

- Pressurized oil lubrication

Requires:

- Air compressor (code 8710)

- Hydraulic KP belt tensioner (code 8381)

Dura Line XCut sawtooth with spiral groove (110/145 teeth) – code 3751

Dura Line XCut sawtooth with spiral groove for whole crop (145/165 teeth) – code 3752

NOTE: Only available for 9000 Series models.The following additional options are also available for the XStream KP.

Temperature monitoring (code 838A)

Temperature monitoring (code 838A)

Crane for KP removal complete with electrical winch (code 8380)

Crane for KP removal complete with electrical winch (code 8380)

Filtro de aire/acelerador de cultivo

| Cantidad de hojas | 10 |

| Speed (option) | 1890 rpm |

| Rotor diameter/housing width | 560 / 620 mm 22,86 / 24,41 in. |

Cabina

| Cámara de refrigeración | Opcional |

| Contador de hectáreas | estándar |

| Limpiaparabrisas lateral | Limpiaparabrisas trasero y lateral opcional Limpiaparabrisas paralelo |

| Inclinación y extensión de la columna de la dirección | estándar |

| Asiento de aprendiz | estándar |

| Sistema de información del operador | Monitor esquinero |

| Ajuste eléctrico y de calefacción | Optional on rearview mirrors |

| Aire acondicionado y calefacción | Standard: ClimaTrak™ control |

| Asiento del operador | Standard: Air-suspension seat |

| CAN bus electronics | estándar |

| Rearview mirrors | estándar |

| Panoramic view windows | estándar |

Sistema de enfriamiento

| Transmisión del ventilador de refrigeración | Directa |

Cabezal de corte

| Velocidad a velocidad nominal del motor | Estándar - 1170 RPM Opcional - 1350 RPM |

| Tipos de cuchillas disponibles (cultivo) | Recto - hierba Curvado - maíz |

| Ancho del tambor de la cuchilla | 850 mm 33,5 pulgadas |

| Tipo | Dura-Drum™ cutterhead |

| Shear bar options | Grass, corn, Dura Line™ corn, Dura Line Plus |

| Diámetro del tambor de la cuchilla | 670 mm 26,4 pulgadas |

Transmisión

| Tensionamiento de la correa | Activo, presión hidráulica |

| Embrague principal | Embrague seco |

| Cantidad de discos | Dos discos |

| Hidráulica | Detección de carga |

| Banda de transmisión principal | Reinforced with Kevlar® inserts |

| Mando motriz | ProDrive™ system, autoshift transmission, differential lock (automatic and manual), automatic wet brake system RPM del motor en carretera: 1200-1800 RPM |

| Banda de transmisión principal, correas Polybelt | Eight grooves |

Sistema eléctrico/sistema eléctrico e hidráulico

| Tipo/voltaje | 12 / 24 V |

| Capacidad del sistema hidráulico | 50 L 13,2 galones |

| Baterías/cantidad de baterías/capacidad | 3 x 174 A-h |

| Alternador | 12 V - 200 A 24 V - 140 A |

Motor

| Sistema de combustible | Conducto común más cuatro válvulas |

| Desplazamiento | 18 L 1.098,43 in³ |

| Tipo | JD18 X Exhaust emission regulations compliancy: Final Tier 4 (FT4)/Stage V |

| Modelo | Europe: 6180ZX501 North America: 6180ZX401 |

| Compresor de aire | Opcional |

| Cilindros | In-line six |

Potencia del motor

| Capacidad del tanque de combustible | 1500 L 396,3 galones |

| Potencia máxima | At 1400 rpm (ECE R120): 607 kW 825 PS / 813 hp Rated Power: 588 kW 800 PS / 789 hp |

| DEF tank capacity ( for FT4 or EU Stage V emission level) | No DEF tank |

Sistema de alimentación/rodillos de alimentación

| Ancho, frontal | 830 mm 32,7 pulgadas |

| Apertura del bastidor del rodillo de alimentación | Abatible, 37-45 grados (ángulo) |

| Número | Cuatro |

| Stone detector | Opcional |

| Detector de metales | estándar |

| Standard feedroll drive | Transmisión hidrostática de rodillos de alimentación IVLOC Infinitely header drive speed |

Mando motriz

| Sistema de freno húmedo automático | estándar |

| Bloqueo del diferencial | Manual y automático |

| Tipo de eje trasero | Hydromechanical 4WD |

| Engine speed management | estándar |

| Velocidad de transporte máxima | ProDrive system: 20/25/30/40 km/h 12,4/15,5/18,6/24,9 mph |

Harvest channel

| Componentes del caudal de cultivo | Low-friction crop flow concept |

| Ancho | Wide body channel |

Header connection

| Maize headers | 8, 10 or 12 rows Working width: 6, 7.5, or 9 m 19.7, 24,6 , or 29,5 ft |

| Multicoupler | estándar |

| Auto PTO coupler | Opcional |

| Control de altura del cabezal | Control de cabezal avanzado (AHC) opcional |

| Lateral pivoting frame | estándar |

| Header drive | Base: Heavy-duty gearbox (i=3,75); pump/motor displacement: 85/80 cc Optional: Extra heavy-duty gearbox (i=4,31); pump/motor displacement: 110/90 cc |

| Grass pickups (transport width) | 3, 4, 4,5 m 9.8, 13.1, 14,8 ft |

| Infinitely variable header drive | estándar |

John Deere Premium KP

| Maize - standard sawtooth or Dura Line™ roll teeth number (speed differential) | 118 (32 or 40 percent) |

| Housing | Standard KP housing |

| Whole crop - standard sawtooth roll teeth number (speed differential) | 178 (32 or 40 percent) |

| Roll diameter | 240 mm 9,45 pulgadas |

| Lubricación | Grasa |

| Peso | 163,3 kg 360 lb |

John Deere XStream KP

| Whole crop - Dura Line XCut roll teeth number (speed differential) | 145/165 (50 percent) |

| Housing | Heavy-duty KP housing |

| Maize - Dura Line sawtooth or XCut roll teeth number (speed differential) | 110/145 (50 percent) |

| Lubricación | Pressurized oil |

| Roll diameter | 250 mm 9,8 pulgadas |

Procesador de granos

| Cambio rápido | Procesador de grano rápido - estacionado/en posición de trabajo |

| Quick KP removal | Optional crane with remote-controlled electric hoist |

| Tipo | John Deere Premium KP™, John Deere XStream KP™ |

Especificaciones clave

| Sistema de combustible | Conducto común más cuatro válvulas |

| Capacidad del tanque de combustible | 1.500 L 396,3 galones |

| DEF tank capacity ( for FT4 or EU Stage V emission level) | No DEF tank |

| Motor | Tipo JD18 X Exhaust emission regulations compliancy: Final Tier 4 (FT4)/Stage V Desplazamiento 18 L 1.098,43 in³ Modelo Europe: 6180ZX501 North America: 6180ZX401 Cilindros In-line six |

| Potencia máxima | At 1400 rpm (ECE R120): 607 kW 825 PS / 813 hp Rated power: 588 kW 800 PS / 789 hp |

Sistema de afilado de cuchillas

| Rotación inversa | sí |

| Automático desde la cabina | Sí, remoto desde la cabina |

| Sharpening modes | Grinding and finishing |

Soluciones de gestión de máquinas

| Control de longitud de corte basado en el parámetro de cultivo | Standard: Infinitely variable length-of-cut (IVLOC™) Optional: AutoLoc™ system - use with HarvestLab |

| Assisted steering systems | Optional: AutoTrac™, Manual RowSense™, AutoTrac RowSense, Machine Sync |

| Análisis del cultivo | HarvestLab™ 3000 optional |

| Monitoreo de rendimiento | Harvest Monitor™ opcional |

| Documentación | Harvest Doc™ opcional |

Mantenimiento

| Duración de cambio del aceite de motor y filtro | 1000 horas |

| Limpiador de pantalla de radiador giratorio | estándar |

| Sistema de lubricación automática | Standard: AutoLube |

Tubo de descarga

| Rotación, grados | 210 grados (ángulo) |

| Desviación de doble tapa | estándar |

| Posición de altura hidráulica | Standard: Hydraulic raise and lower Optional: Automatic spout positioning |

| Reach from center line (Optional) | 6 or 8 row: 4,73 m 15,5 ft 10 row: 5,87 m 19,3 ft 12 row: 6,71 m 22 ft |

| Altura de trabajo (máxima) | Altura hasta el tubo de descarga: 6,6 m 21,65 ft |

Vehículo

| Longitud de transporte (sin cabezal) | 6,6 m 21,7 ft |

| Ancho de transporte (sin cabezal) | 3,2-3,8 m 10,5-12,5 ft |

| Altura de transporte (hasta el techo de la cabina) | Below 4 m 13,12 ft |